-

Belt Delivery Machinery Equipment +

-

Belt Conveying Machinery Fitting +

-

Crush Machines +

-

Sieving Machines +

-

Breaking and Sieving Unit +

-

Ball Mill Equipment +

-

Industrial and Mining Electric Locomotive +

-

Fuel Conveying System of Biomass Power Generation

-

EPC General Contracting Scheme +

-

Electrical control components +

-

Circular economy

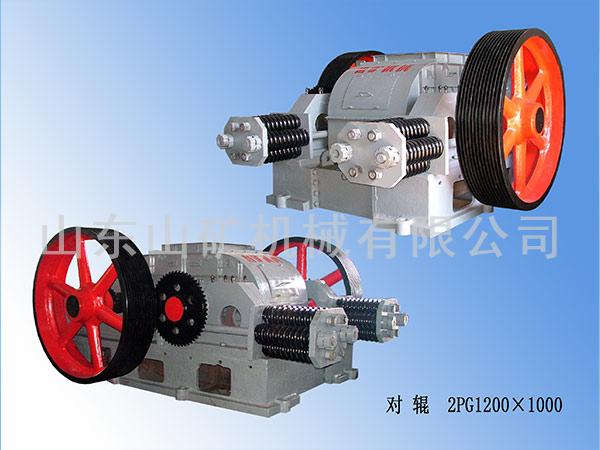

Roll crusher (senior roller)

Roll crusher (senior roller)

Main characteristics of double-roll crusher: compact structure, steady running, long service life, steady quality, flexible and adjustable grain size, and easy to maintain etc.

The rotation of the machine is realized by motor driving the drive roller with the help of fluid coupling and reducer, and the drive roller driving the driven roller by gearbox. The two rollers run face to face with different rotation. The feeing material drop through the rollers, after squeezed, then the finished material discharged naturally, when there are some over-hard or non-breaking material appear, the roller gap can be enlarged with the contractive action of spring automatically, so the over-big or non-breaking material pass to the discharging exit and the machine is well protected. There is relative gap between the rollers running face to face, we can control the max. discharge grain size by change the gap. We can break the material of 40mm to under 10mm. In order to prolong the service life, the roller should be high quality wearable alloy cast steel structure and its surface performs quenching and high temperature tempering treated. For bearing seal, adopts 2-layer seal ring structure, which need not fill lubrication oil for long time.

The main parts are: drive unit, fixed shaft assembly, mobile shaft assembly, hood assembly, frame assembly, linkage and safety device and gearbox etc. parts, which are widely used in cement, metallurgy, chemical industry, power plant, coal etc. industries to break and process the brittle and tough material.

2PG1200×1000 double-roll crusher was the Shandong province innovation plan project carried out by our company in 2004, and it has passed the provincial new product appraisal by the end of 2004.

|

|

Inlet grain size |

Discharge |

Crushing |

Revolution |

Weight |

Motor |

Dimensions |

|

|

Type |

Power |

|||||||

|

400×250 |

32 |

0-8 |

5-10 |

200 |

1100 |

Y160-6 |

11 |

1450×1250×830 |

|

610×400 |

85 |

0-30 |

13-40 |

75 |

3700 |

Y225M-6 |

30 |

3545×1700×815 |

Gear-roll crusher is suitable for coal, metallurgy, mining, chemical industry and construction material etc. industries, and even more suitable to break the raw coal (including gangue) of large coal mine or coal dressing plant. This kind of crusher is a new product independently designed by our company on the basis of consulting the structure principle of overseas crusher.

The machine has the advantages of small volume, big breaking ratio (5-8), low noise, simple structure, easy to maintain, and the characteristics of high productivity (higher 1-2 times than domestic 2PGC gear-roll crusher), even discharged grain size, low over-breaking percent, easy to maintain, sensitive over-load protection, safe and reliable etc. The working principle of this machine is that special wearable gear rollers run face to face in high speed to break the material.

This double-gear roll crusher is driven by universal coupling, the gap between rollers can be adjusted by add or reduce washers. The main parts are fixed roller, mobile roller, reducer, universal coupling. Adopting sliding bearing with the advantages of steady driving, and very convenient for maintenance.

2PGCQ625×3000 strong double-gear roll crusher designed by our company has the advantages of compact structure, big breaking ratio (5-8), low energy consumption, low noise, simple structure, easy to maintain, and the characteristics of high productivity (higher 1-2 times than domestic 2PGC gear-roll crusher), even discharged grain size, low over-breaking percent, easy to maintain, sensitive over-load protection, safe and reliable etc., which filled the gap in domestic same industry, and its main performance index are among the top level of domestic industry. The main innovation aspects:(1)for the teeth plate is alloy material of high wearable and high strength performance, which prolong the service life of crusher;(2)improve the teeth height and teeth pitch on the basis of former crusher, and in this way the breaking ability is enhanced greatly;(3)upgrade the lubrication oil system, equip the dry oil lubrication station, make sure the automatic oil filling activity can be achieved when starting the machine;(4)has the auto-alarming function, if the other parts of lubrication oil have some problems, then it can alarm automatically.

2PGCQ625×3000 strong double-gear roll crusher was the Shandong province innovation plan project carried out by our company in 2004, and it has passed the provincial new product appraisal by the end of 2004. In 2005, 2PGCQ625×3000 strong double-gear roll crusher won national No. 10th enterprise new record.

|

Technical Spcifications |

Inlet grain size |

Discharge gain size |

Capacity |

Power |

Roller |

Weight |

|

Φ450×500A |

0-100 |

0-25 |

20 |

11 |

64 |

3.2 |

|

0-200 |

0-50 |

35 |

||||

|

0-75 |

45 |

|||||

|

0-100 |

55 |

|||||

|

Φ600×750 |

0-300 |

0-50 |

60 |

22 |

50 |

6.95 |

|

0-75 |

80 |

|||||

|

0-600 |

0-100 |

100 |

||||

|

0-125 |

125 |

|||||

|

Φ900×900 |

0-800 |

0-100 |

125 |

30 |

37.5 |

13.27 |

|

0-125 |

150 |

|||||

|

0-150 |

180 |

|||||

|

Φ900×900 |

0-800 |

0-110 |

250 |

55 |

65.5 |

12.603 |

|

Φ500×1500 |

0-300 |

0-50 |

200-350 |

2×37 |

48 |

12.2 |

|

Φ1000×1500 |

200 |

50 |

200 |

75 |

60 |

26.553 |

|

Φ625×3020 |

≤300 |

50 |

400 |

2×160 |

78 |

23.80 |

The main characteristics of 4PG series tetra-roll crusher: simple breaking flow, low operation cost, long service life, steady quality, adjustable discharge grain size and easy to maintain.

The rotation of the machine is realized by 2 motors driving the upper drive roller and bottom drive roller with the help of coupling and reducer. The feeing material drop through the rollers, after squeezed, then the finished material discharged naturally, when there are some over-hard or non-breaking material appear, the roller gap can be enlarged with the contractive action of spring automatically, so the over-big or non-breaking material pass to the discharging exit and the machine is well protected. There is relative gap between the rollers running face to face, we can control the max. discharge grain size by change the gap. We can break the material of 100mm to less than 3mm.

In order to prolong the service life, the roller should be high quality wearable alloy cast steel structure and its surface performs quenching and high temperature tempering treated. If the roller surface is frayed, it also can perform cutting activities by the turning device equipped with the machine to keep the surface smooth. For bearing seal, adopts 2-layer seal ring structure, which need not fill lubrication oil for long time.

The main parts are frame part, drive roller part, driven roller part, drive part, safe adjustment part, protection hood and turning part etc. It has been widely used in cement, metallurgy, chemical industry, power plant and coal etc. industries to break the crisp and tough material.

4PGφ900X700 tetra-roll crusher was the Shandong province innovation plan project carried out by our company in 2003, and it has passed the provincial new product appraisal by the end of 2003.

4PG1200×1000 tetra-roll crusher was the Shandong province innovation plan project carried out by our company in 2004, and it has passed the provincial new product appraisal by the end of 2004.

The series of 4PGC Tetra-Gear Roll Crusher is characterized by novel design, reasonable construction, large crushing capacity, high efficiency in technology and good economic benefit. It is a new type of crushing equipment, possessing the features of high efficiency, advanced technology and energy saving. This crusher is of a 2-step operation performed within the same frame of the machine with a crushing ratio 6-8 and a crushing efficiency of 99% or over.

This series of crushers have been widely used in coal, metallurgy, chemical industries and non-metallic mines to crush the materials of medium hardness such as lump coal, coke, shale, chalk, graphite, kaolin and asbestos. On account of the size of products crushed by our series of crushers are especially even, the phenomena of extra size or exceedingly smashed are quite rare, therefore it is suitable for the raw coal to be crushed before the coal dressing and classification.

Main technical index:

|

Crushing materials |

Medium hard material,ore,rock,limestone,slag,slaked lime,etc. |

|||

|

Capacity |

Upper roll clearance is 40mm,bottom roll clearance is 10mm |

≈18 |

||

|

Upper roll clearance is 10mm,bottom roll clearance is 2mm |

≈16 |

|||

|

Feeding frain size |

Upper roll clearance is 40mm |

≈100 |

||

|

Upper roll clearance is 10mm |

≈40 |

|||

|

Motor |

Type |

Drive upper roll |

YD250M-12/6 |

|

|

Drive bottom roll |

Y225M-6 |

|||

|

Power |

During breaking |

Upper roll |

24 |

|

|

Bottom roll |

30 |

|||

|

Cutting |

15 |

|||

|

Rotational speed |

Breaking |

990 |

||

|

Cuting |

490 |

|||

|

Roller's rotaional speed when breaking |

Upper drive roll&upper driven roll |

96 |

|

Upper drive roll&bottom driven roll |

173 |

|

|

Roller's rotaional speed when cuting |

Upper drive roll&upper driven roll |

51 |

|

Bottom drive roll&bottom driven roll |

51 |

|

|

reducer for upper drive gear |

ZQ50-10 II |

Drive ratio i=10 |

|

Reducer for bottom drive gear |

ZD30-10 I |

Drive ratio i=5.6 |

|

Weight |

2800 |

|

|

Dimensions(mm) |

3150×1980×3147 |

|

MORE PRODUCTS

Messages

WRITE A MESSAGE TO US

Shandong Shankuang Machinery Co.,Ltd

Webpage Copyright:Shandong Shankuang Machinery Co.,Ltd 鲁ICP备11032345号

+86-537-2228209

+86-537-2228209

Messages

Messages