-

Belt Delivery Machinery Equipment +

-

Belt Conveying Machinery Fitting +

-

Crush Machines +

-

Sieving Machines +

-

Breaking and Sieving Unit +

-

Ball Mill Equipment +

-

Industrial and Mining Electric Locomotive +

-

Fuel Conveying System of Biomass Power Generation

-

EPC General Contracting Scheme +

-

Electrical control components +

-

Circular economy

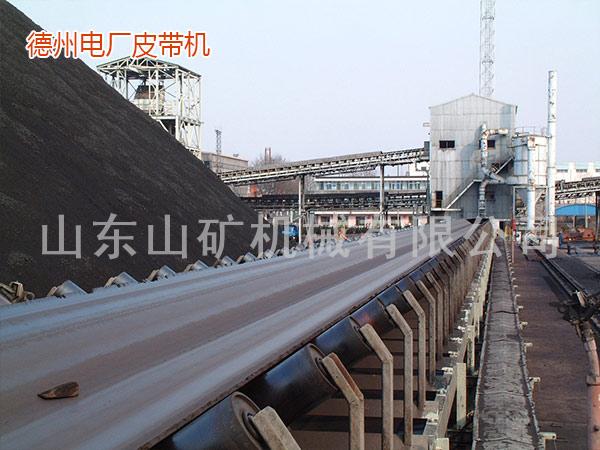

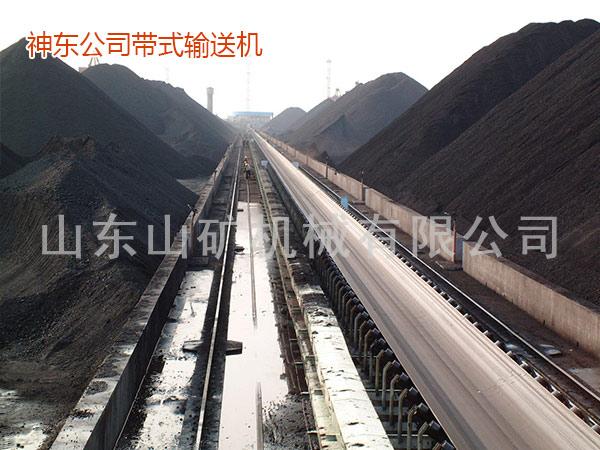

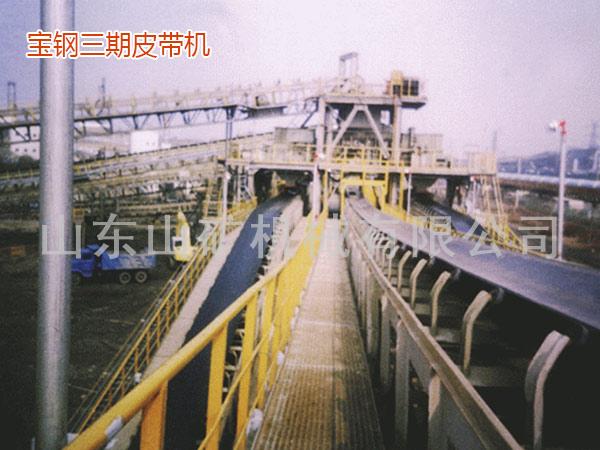

General belt conveyor

General belt conveyor

For our company general belt conveyor, there are TD75、DTII、DTII(A)、DX、 JKD、ZJT-86 series. The total design of our belt conveyor is according to the requirement of 《Belt conveyor technical specification book》, follows the relative standard and technical safety specification of current fire power plant, metallurgy, port etc. industries, uses the ripe design experience of domestic and international companies for reference, combines the specific requirement and special climate condition and working condition of project to design and make sure the equipment can meet the requirements of safe and reliable operation and running

During our design, we mainly refer to 《JKD92 Belt conveyor design and selection manual》, which is based on 《JKD85 Belt conveyor design and selection manual》 and combined with 《DT75 Type fixed belt conveyor design and selection manual》、《DX Type strong belt conveyor design and selection manual》、《80 Coal conveying part typical design and selection manual》、《87 Coal conveying part typical design and selection manual》、《DTII Type fixed belt conveyor design and selection manual》、《D-YM96 Coal conveying part typical design and selection manual》、《DTII(A)Type fixed belt conveyor design and selection manual》 etc. documents and combined with our own many years design, manufacture and equipment running experiences, and compiled by many senior and medium professional technicians, and this manual has been widely used.

For long distance, large capacity and complex layout belt conveyor, we will carry out the dynamic analysis, consider the effect of several factors, such as the mechanical property of belt, the start and brake characteristics of drive unit, quality distribution of all moving part, gradient variation of running line at different segment, all moving resistance, the initial tension of belt, flexibility variation of belt, the method, position and tension of take-up unit, make a dynamics math model of belt conveyor to calculate the variation of speed, acceleration and tension at different point of belt during the process of start and brake of belt conveyor. We can predict possible dynamic danger and unsafe problems for the belt conveyor designed according to traditional static design method, and put forward improve and adjust measures to this design to decide the optimized design and control data.

Many drive scheme: for long distance belt conveyor with complex running line, the normal drive scheme can not meet the requirement of start and running, we’d better adopt such drive unit with controllable start and brake function to control the belt conveyor and make sure it can be started and braked according to the ideal start and brake speed curve, and in this way, we can decrease the dynamic load of belt and carrying parts. The main methods are: solid state step-down soft start method, AC frequency conversion speed adjustment drive method, CST controllable start and brake method, soft start method of winding motor series-wound resistor in rotor circuit, liquid viscosity soft start method, hydraulic motor drive method and fluid coupling drive method etc.

Main technical index:

|

JKD Type Bandwidth B=500-2200 DT75Type Bandwidth B=500-1400 DTII Bandwidth B=500-1400 DTII(A) Type Bandwidth B=500-1400 ZJT-86 Bandwidth B=500-1400 Conveyor Parameters |

|||||||

|

Volume selection (press belt speed m / s, the level of β = 0) |

|

|

|

|

|||

|

Bandwidth(mm) |

Angle of repose |

Shipments C=m3/h |

|||||

|

Idlers groove angle |

|||||||

|

20° |

25° |

30° |

35° |

40° |

45° |

||

|

500 |

0° |

36.2 |

44.2 |

|

|

|

|

|

|

15° |

72.5 |

79.3 |

|

|

|

|

|

|

30° |

81.6 |

89.2 |

|

|

|

|

|

650 |

0° |

67.4 |

82.2 |

95.8 |

|

|

|

|

|

15° |

132 |

144.5 |

155.3 |

|

|

|

|

|

30° |

148.5 |

162.6 |

175.9 |

|

|

|

|

800 |

0° |

105.3 |

128.5 |

149.8 |

168.7 |

|

|

|

|

15° |

206.7 |

226.3 |

243.2 |

257.2 |

|

|

|

|

30° |

232.5 |

254.6 |

275.5 |

289.4 |

|

|

|

1000 |

0° |

173.8 |

212 |

246.8 |

227.8 |

304.5 |

326.7 |

|

|

15° |

336.7 |

368.7 |

396.2 |

418.9 |

436.6 |

449.1 |

|

|

30° |

378.8 |

414.8 |

444 |

471.3 |

491.2 |

505.2 |

|

1200 |

0° |

254.1 |

309.9 |

360.9 |

406.2 |

445.4 |

478 |

|

|

15° |

493.3 |

540.1 |

580.5 |

613.8 |

639.8 |

658.3 |

|

|

30° |

555 |

607.6 |

650 |

690.5 |

719.8 |

740.6 |

|

1400 |

0° |

355.6 |

433.6 |

504.6 |

567.6 |

521.9 |

666.8 |

|

|

15° |

685.2 |

750.4 |

806.5 |

852.6 |

888.2 |

913.2 |

|

|

30° |

770.9 |

844.2 |

900 |

655.4 |

999.2 |

1027.4 |

|

1600 |

0° |

472.3 |

575.7 |

669.8 |

753.3 |

825 |

884.1 |

|

|

15° |

906.9 |

993.4 |

1067.5 |

1128.4 |

1175.3 |

1207.9 |

|

|

30° |

1020.3 |

1117.6 |

1190 |

1269.5 |

1322.2 |

1358.9 |

|

1800 |

0° |

605.5 |

737.9 |

858.4 |

965.1 |

1056.6 |

1132 |

|

|

15° |

1159.6 |

1270.2 |

1365 |

1442.6 |

1502.3 |

1543.6 |

|

|

30° |

1304.6 |

1429 |

1535 |

1622.9 |

1690.1 |

1736.6 |

|

2000 |

0° |

751 |

915.3 |

1064.7 |

1197.2 |

1310.9 |

1404.6 |

|

|

15° |

1439.5 |

1567.8 |

1694.5 |

1791 |

1865.2 |

1916.6 |

|

|

30° |

1619.4 |

1773.9 |

1920 |

2014.9 |

2098.4 |

2156.2 |

MORE PRODUCTS

Messages

WRITE A MESSAGE TO US

Shandong Shankuang Machinery Co.,Ltd

Webpage Copyright:Shandong Shankuang Machinery Co.,Ltd 鲁ICP备11032345号

+86-537-2228209

+86-537-2228209

Messages

Messages