-

Belt Delivery Machinery Equipment +

-

Belt Conveying Machinery Fitting +

-

Crush Machines +

-

Sieving Machines +

-

Breaking and Sieving Unit +

-

Ball Mill Equipment +

-

Industrial and Mining Electric Locomotive +

-

Fuel Conveying System of Biomass Power Generation

-

EPC General Contracting Scheme +

-

Electrical control components +

-

Circular economy

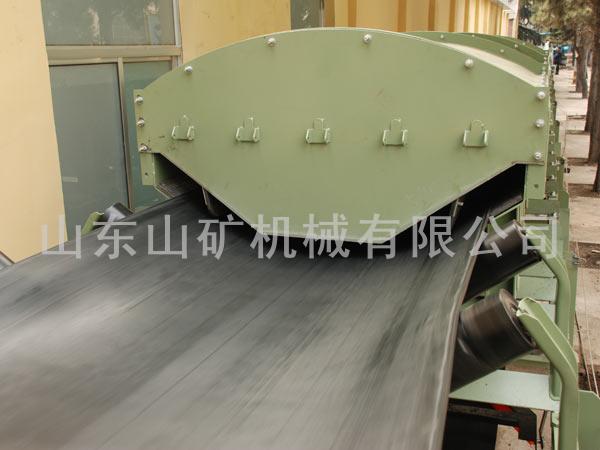

Domestic ∮ 800mm pipe belt conveyor

Domestic ∮ 800mm pipe belt conveyor

SKGD∮800 tubular belt conveyor

In 2015, Shankuang Company successfully designed and developed a pipe belt machine with the largest pipe diameter of ∮800mm in China, and made a prototype for installation and operation in the company's courtyard. The product is widely used in electric power, building materials, chemical industry, metallurgy, mining, coal, port, Food and other industries. According to the investigation, the maximum pipe diameter of the domestic pipe belt machine is only 600mm, and the capacity is 2500-3200t/h; the maximum pipe diameter of the international pipe belt machine is 700mm, and the capacity is 4200t/h. Bridgestone) company design and manufacture.

1. Main technical parameters of SKGD∮800 pipe belt machine:

|

Pipe diameter |

dg=800mm |

horizontal length |

L=60m |

|

bandwidth |

B=2800mm |

lift height |

H=3m |

|

belt speed |

V= 3.15m/s |

slope |

Β=2.86˚ |

|

Maximum delivery volume |

Q= 3600³/h |

tensioning device |

Heavy hammer tensioning device |

2. The main structure and characteristics of this pipe belt machine

This pipe belt machine is mainly composed of driving device, transmission roller, redirecting roller, idler group, tensioning device, cleaner, headstock, tailstock, head transition section, tail transition section, standard section and conveyor belt. .

①The driving device is the motive power part of the pipe belt machine, which can be composed of electric motor, reducer, high-speed coupling (hydraulic coupling or plum blossom elastic coupling), low-speed shaft coupling, brake, backstop, etc. Sometimes according to user requirements, a low-speed high-torque permanent magnet synchronous motor can also be used, which has the advantages of energy saving and high efficiency, small size, light weight, high torque density, high efficiency power factor, strong overload capacity, etc., and the driving efficiency is increased by more than 10%. .

②The head of the pipe belt machine adopts several adjustable transition roller sets and pressure roller sets to guide the circular conveyor belt into a parallel conveyor; the tail adopts several adjustable transition roller sets to gradually guide the parallel conveyor belt into a closed circle. shaped section.

③The pipe section of this pipe belt machine adopts a regular hexagonal idler group, and the idler rollers are arranged on both sides of the idler window frame, with three idler rollers on each side.

④ This pipe belt machine has been reasonably analyzed from the aspects of drive configuration, spacing arrangement of forming rollers, structural form of steel truss, longitudinal rigidity and transverse rigidity of the tape, and maintaining the degree of circularity. In the transition section of the tape, the process of forming a tube and various properties of the tape are demonstrated dynamically by computer. In this way, the pipe belting machine not only has high capacity and stable operation, but also has a compact structure and reduced cost.

⑤ The pipe belt conveyor has a large conveying capacity, such as conveying large-density materials such as ore, and the conveying capacity can reach tens of thousands of tons per hour.

MORE PRODUCTS

Messages

WRITE A MESSAGE TO US

Shandong Shankuang Machinery Co.,Ltd

Webpage Copyright:Shandong Shankuang Machinery Co.,Ltd 鲁ICP备11032345号

+86-537-2228209

+86-537-2228209

Messages

Messages